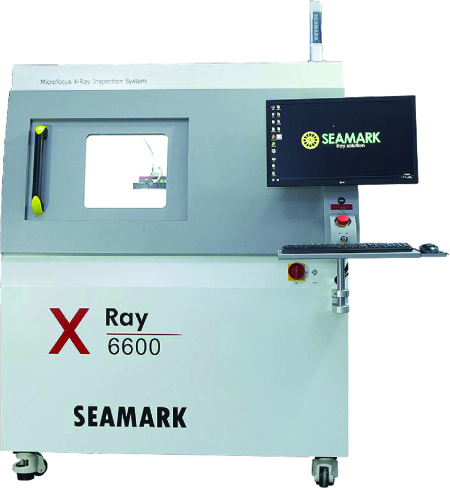

X-Ray Solution X6600

The X-Ray Solution X6600 is a high-resolution, non-destructive inspection system designed for detecting internal defects in Printed Circuit Boards (PCBs), semiconductor components, and electronic assemblies. This system uses advanced X-ray imaging technology to penetrate materials and provide detailed internal structural analysis.

With automated defect detection, high magnification imaging, and 360-degree rotational inspection capabilities, the X6600 ensures superior quality control for electronic manufacturing, ensuring soldering accuracy, void detection, BGA/SMT component inspection, and failure analysis.

Product Features

- High-Resolution X-Ray Imaging – Provides clear, high-magnification internal images of electronic components.

- Non-Destructive Inspection – Allows thorough internal analysis without damaging the sample.

- Advanced 360° Rotational Imaging – Enables comprehensive multi-angle inspection for hidden defects.

- Automated Defect Detection – AI-powered software identifies cracks, solder voids, and misplaced components.

- Real-Time Analysis & Reporting – Integrated SPC software for real-time defect tracking and data logging.

- User-Friendly Interface – Touchscreen and Windows-based software for easy operation.

- Adjustable X-Ray Power – Optimized for various materials and component densities.

- Compact & Safe Design – Fully shielded X-ray chamber ensures operator safety.

Product Applications

- Electronics & Semiconductor Industry – Inspection of BGA, QFN, CSP, LED, and SMT components.

- Automotive Electronics – Ensuring reliability in ECU, power modules, and sensor assemblies.

- Aerospace & Defense – High-precision defect detection for mission-critical electronics.

- Medical Devices – Inspection of PCBs used in diagnostic and imaging equipment.

- Industrial Manufacturing – Quality control in high-reliability electronics and telecommunications hardware.